Featured Products

$27.50

$164.00 NEW

$98.00

$520.00

Engine Harness (Bosch Alternator)

$405.00 NEW

Engine Harness (Motorola Alternator)

$405.00

Front Harness - Washer Motor, Front Left (1965-68)

$415.00 NEW

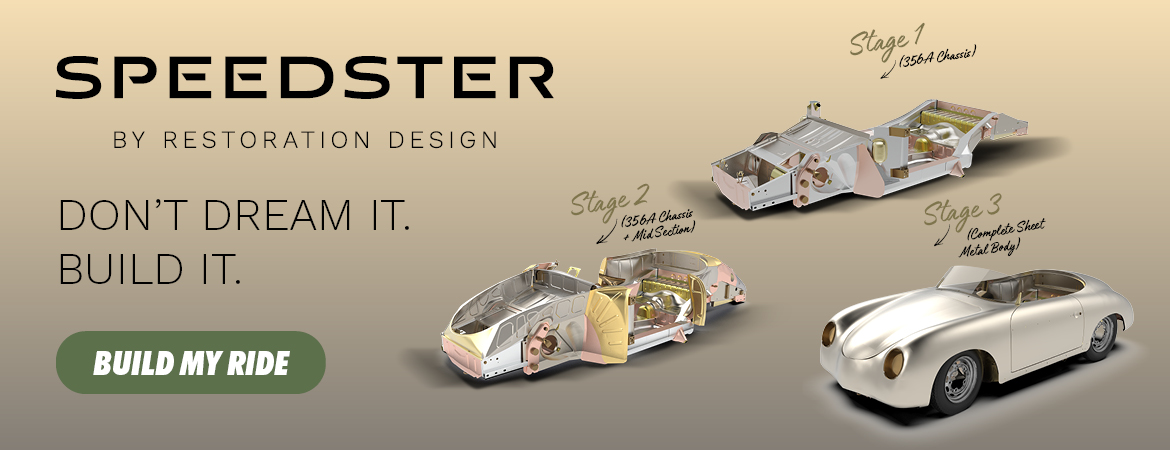

Restoration Design Videos

Visit our Youtube site today for a ton of great information. We have produced over 30 videos for the Porsche enthusiast and are constantly adding insightful new content. Learn about specific installations for many of our panels, the benefits of Gavanneal Steel over conventional steel, and in-depth spotlights on our own collection of cars. Restoration Design is proud to share our love of the Porsche family with you!